Scarfing Inserts Market Set for Steady Growth Through 2035, Backed by Steel Sector Innovation and Automation Demand

Demand for scarfing inserts grows with rising automation and steel output, driving efficiency in surface defect removal operations.

NEWARK, DE, UNITED STATES, August 6, 2025 /EINPresswire.com/ -- Scarfing Inserts Market Powers Forward with Precision and Performance as Steel Sector Demands More

The scarfing inserts market is projected to grow from USD 263.8 million in 2025 to USD 383.1 million by 2035, registering a CAGR of 3.8% during the forecast period. This moderate growth is expected to be driven by consistent demand from the steel manufacturing and metal processing industries.

As global steel production evolves to meet higher quality standards, manufacturers are leaning heavily on one unsung hero of the process scarfing inserts. These precision tooling components are becoming indispensable for steelmakers focused on surface conditioning, weld bead removal, and defect elimination across hot and cold rolling operations. According to new market insights, the scarfing inserts market is on a stable growth trajectory from 2025 to 2035, driven by innovation in materials, automation, and increasing demand from high-growth regions like India and China.

Enabling Clean Cuts, Consistent Quality

Scarfing inserts play a critical role in continuous casting, billet processing, and tube production lines, where a smooth surface finish is essential. As quality demands grow in sectors like automotive, construction, and pipelines, the reliability of scarfing inserts has become non-negotiable. Manufacturers are depending on external scarfing inserts, particularly for structural tubing, which remains the top application segment, to meet high machining efficiency and lower scrap rates.

Tungsten Carbide Emerges as the Material of Choice

At the heart of this evolution is the dominance of tungsten carbide. Renowned for its wear resistance and thermal stability, tungsten carbide is expected to account for the majority of the market. From high-speed billet processing in China to rebar and wire rod manufacturing in India, this material ensures consistent performance across heavy-duty applications. Its role is central to reducing downtime and extending tool life in automated mills.

Standardization Boosts Manufacturing Efficiency

Steelmakers are also moving toward standard fit inserts, with compatibility and interchangeability driving down inventory costs and increasing operational efficiency. As lean manufacturing principles take root, this segment's growth is further cemented by widespread adoption in tubing production for the construction and energy sectors.

Strong Momentum in Growth Markets

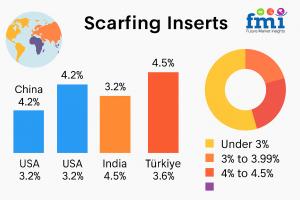

Emerging markets are shaping the next decade of scarfing innovation:

- India leads with a CAGR of 4.5%, supported by integrated steel plant upgrades and an increasing need for defect control in billet and bloom production.

- China is close behind, optimizing continuous casting lines with advanced carbide formulations and reducing surface rejection rates.

- The USA is modernizing scarfing equipment in electric arc furnace facilities, targeting specialty steel applications in automotive and aerospace.

- Türkiye and Japan continue to invest in precision tools, balancing cost-efficiency with advanced processing needs for export-driven and high-grade steel production respectively.

Strategic Shifts Among Manufacturers

Key industry players are sharpening their focus on innovation. Kent Corporation, CERATIZIT Group, Widia, Hunan Estool, and OMCD Group are expanding their footprint through advanced coatings, multi-edge geometries, and customized tooling. These enhancements are aimed at increasing cutting speed, minimizing downtime, and ensuring high repeatability in automated lines.

The scarfing inserts market is moderately consolidated but evolving rapidly through strategic collaborations between insert makers and steel producers. These partnerships are essential for the co-development of solutions that address both surface finish quality and cost-efficiency—key priorities for today's steel mills.

Toward a Cleaner, Smarter Future

Recent developments highlight a sustainability angle too. In February 2025, Norton Abrasives India introduced a sustainable scarfing solution using diamond and CBN abrasives, reducing material waste and enhancing carbon efficiency in the steel sector. As manufacturers worldwide look to balance performance with environmental goals, such innovations are likely to shape future demand.

Request Scarfing Inserts Market Draft Report- https://www.futuremarketinsights.com/reports/sample/rep-gb-22406

For more on their methodology and market coverage, visit- https://www.futuremarketinsights.com/about-us

Conclusion

In a world where steel quality is synonymous with product reliability, scarfing inserts are becoming strategic tools for manufacturers. With demand rising from infrastructure, transportation, and energy projects, manufacturers are turning to these inserts not just to remove defects—but to unlock greater throughput, consistency, and long-term profitability.

Explore Related Insights

Die Bonder Equipment Market- https://www.futuremarketinsights.com/reports/die-bonder-equipment-market

Carbon Free Hose Market- https://www.futuremarketinsights.com/reports/carbon-free-hose-market

Boiler Safety System Market- https://www.futuremarketinsights.com/reports/boiler-safety-system-market

Carbon Brush Market- https://www.futuremarketinsights.com/reports/carbon-brush-market

Thermal Profiling System Market- https://www.futuremarketinsights.com/reports/thermal-profiling-system-market

About Future Market Insights (FMI)

Future Market Insights (FMI) is a leading provider of market intelligence and consulting services, serving clients in over 150 countries. FMI is headquartered in Dubai and has delivery centers in the United Kingdom, the United States, and India. FMI's latest market research reports and industry analysis helps businesses navigate challenges and make critical decisions with confidence and clarity amidst breakneck competition. Our customized and syndicated market research reports deliver actionable insights that drive sustainable growth. A team of expert-led analysts at FMI continuously tracks emerging trends and events in a broad range of industries to ensure that our clients prepare for the evolving needs of their consumers.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Rahul Singh

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.